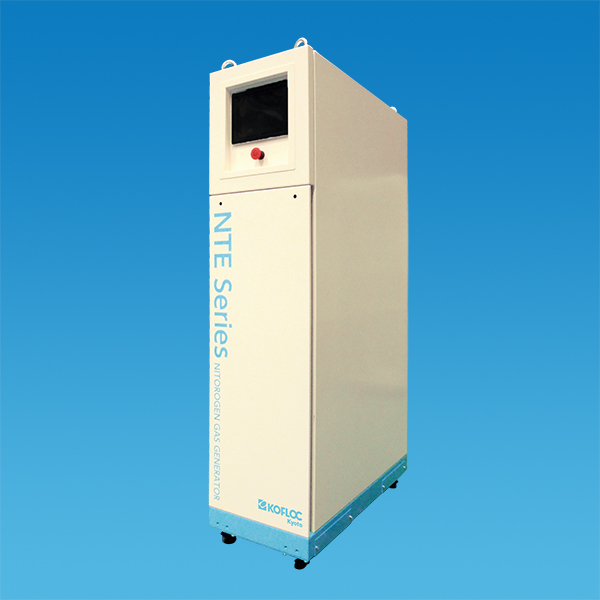

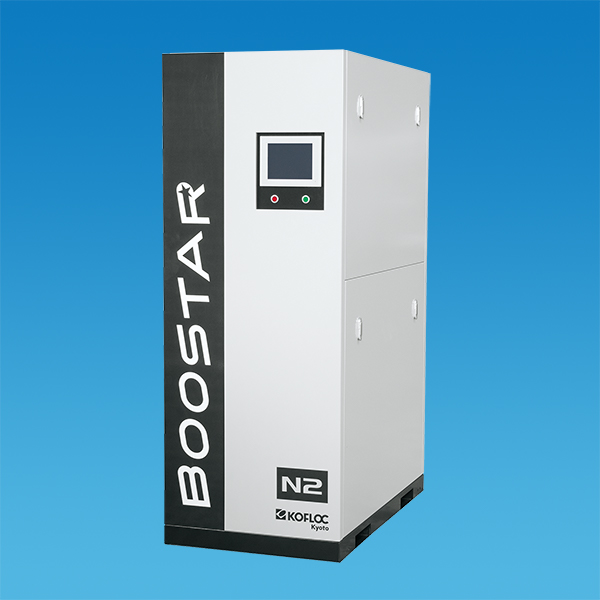

PRODUCTS

N₂ Gas generators

The nitrogen gas generator supplies high-purity nitrogen gas (95 to 99.999%) by extracting nitrogen gas from the air. As compared with methods using cylinders or liquid nitrogen, this product, which enables users to obtain nitrogen gas onsite, can save the cost and effort of management and operation, and reduce CO₂ emissions associated with transportation.