Facing Challenges in Precision Flow Control?

- I want to precisely control gas and liquid flow to improve product quality and reduce costs.

- I'm searching for flowmeters and valves optimized for new equipment or system design.

- I need to handle corrosive gases and chemicals safely, but I’m unsure which products are compatible.

- I’m considering a flow control system to enable automation and reduce manual labor.

- We want to reduce contamination and improve semiconductor yield rates.

Supporting Advanced Semiconductor Manufacturing.

To manufacture high-performance semiconductors, precise control of various gases and liquids is required throughout the production process.

Fluid measurement and control equipment plays a crucial role in many stages of semiconductor manufacturing.

Here are just a few examples of our solutions.

If you are facing any challenges related to fluid measurement or control, please don’t hesitate to contact us.

Usage Example

-

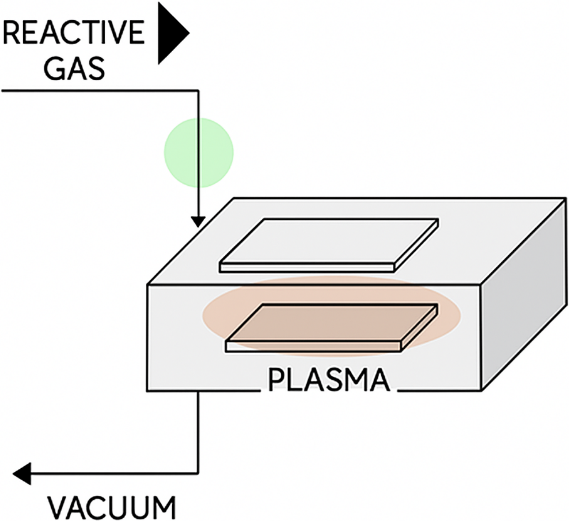

Dry Process

Reactive Gas Control for CVD and Etching Processes

In processes such as Chemical Vapor Deposition (CVD) and etching, reactive gases are introduced into the chamber to trigger precise chemical reactions—forming thin films on the wafer surface or etching desired patterns.

Mass flow controllers used in these processes must not only provide high accuracy and fast response but also withstand corrosive gases, maintain stability under fluctuating pressures, support industrial communication networks such as DeviceNet, and be compatible with integrated gas systems.

At KOFLOC, we develop new control algorithms and comply with industry standards to meet these demanding requirements, continually advancing our product lineup to support next-generation semiconductor manufacturing.

-

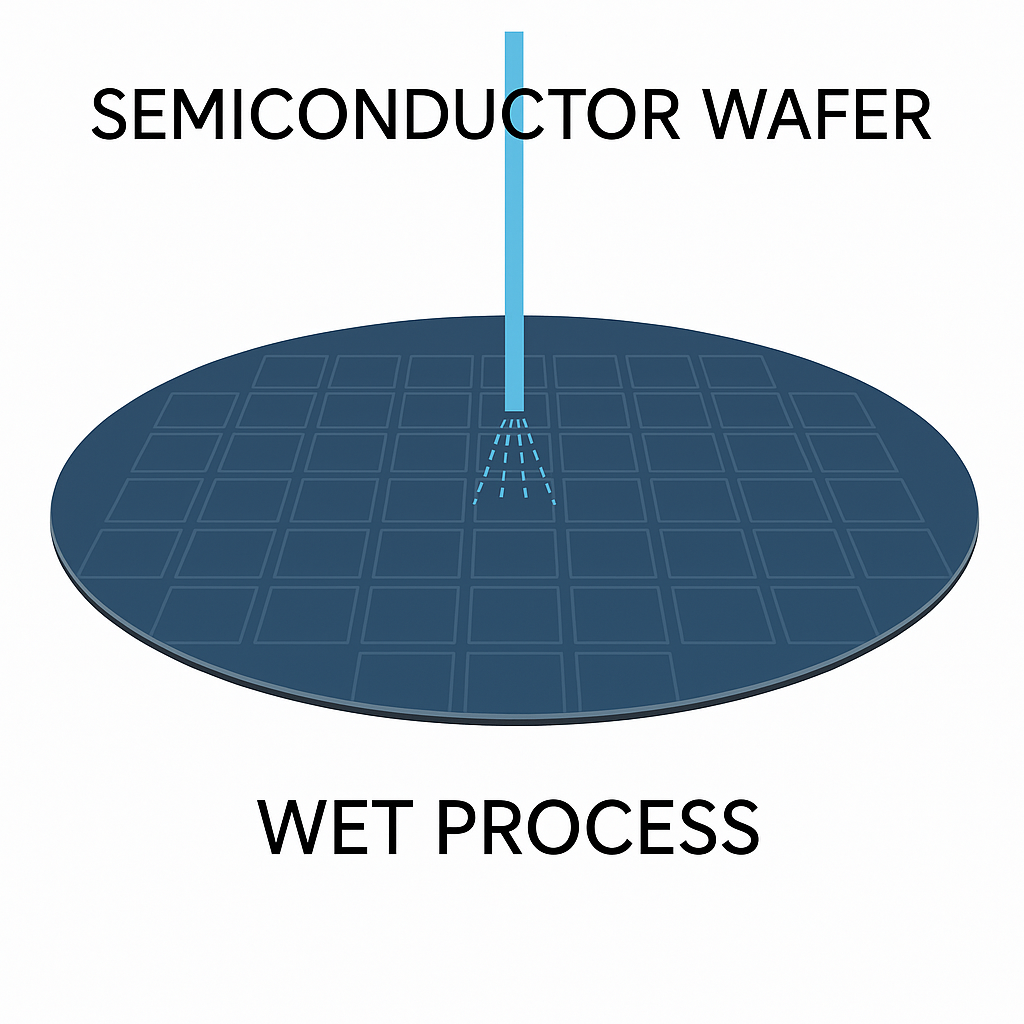

Wet Prosess

Measurement and control of ultrapure water and chemical solutions in cleaning processes

In the cleaning process, impurities remaining on the wafer surface are removed using ultrapure water and chemical solutions.

Materials with excellent chemical resistance are essential, and as semiconductor processes become more advanced, there is a growing need for precise measurement and control of flow rate, pressure, and temperature.

In addition, stricter requirements are emerging for cleanliness performance, including reduced contamination residue.

At KOFLOC, we are actively developing products that meet these diverse and demanding requirements to support stable and high-purity cleaning operations.

Karman vortex flowmeters are widely used for measuring liquid flow, but they have traditionally faced challenges with accuracy due to temperature fluctuations.

KOFLOC’s FML-300 series Karman vortex flowmeter addresses this issue by incorporating a built-in temperature sensor. This allows the device to correct measurement errors caused by temperature changes, enabling highly accurate flow measurement of ultrapure water and chemical solutions.

-

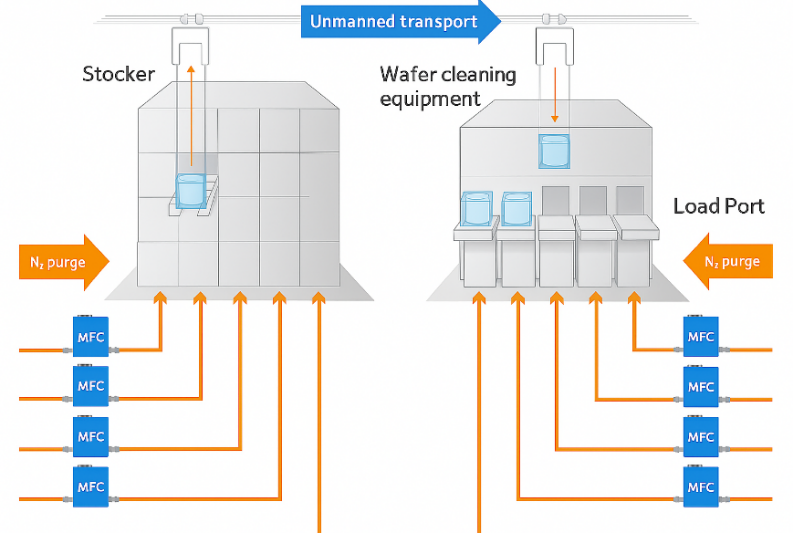

Wafer Handling Systems

Measurement and control of purge gases for load ports and stockers

To manufacture high-quality semiconductors, strict contamination control is essential to prevent wafer surface defects caused by microscopic airborne particles.

Wafers are transported between semiconductor processing tools in fully sealed pods known as FOUPs (Front Opening Unified Pods).

To maintain a clean environment during transfer, nitrogen (N₂) purge gas must be precisely measured and controlled using mass flow controllers.

KOFLOC’s MODEL 3660 Series digital mass flow controllers are compact, highly responsive, and offer excellent accuracy and stability.

With support for digital communication protocols and outstanding corrosion resistance, the 3660 Series is an ideal solution for precise purge gas control in wafer handling systems such as load ports and stockers.

-

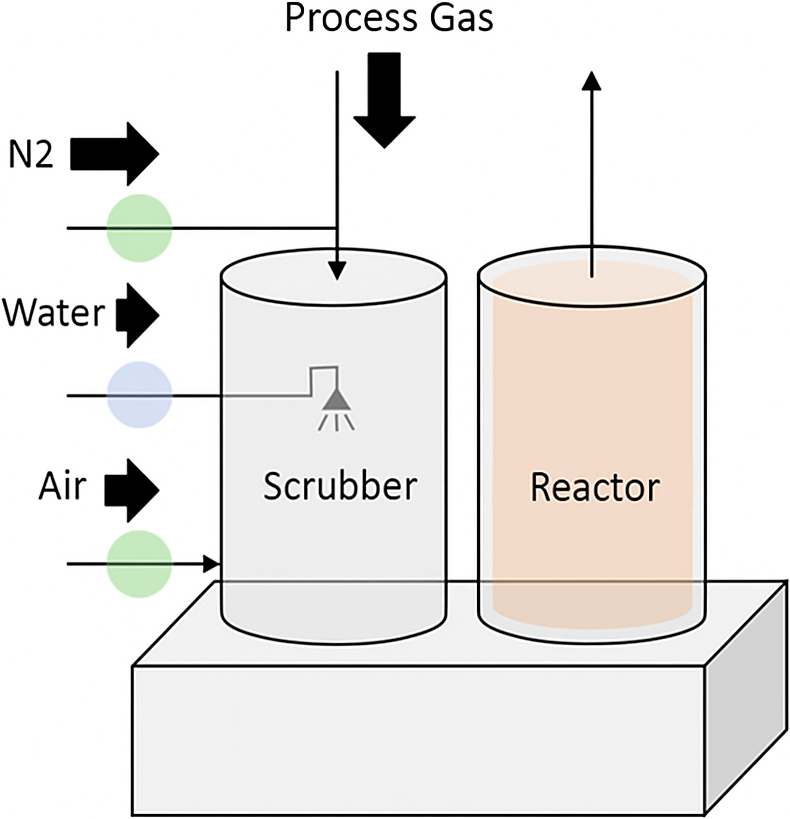

Exhaust Gas Treatment

Measurement and control of dilution gases, reactive gases, cooling water, and circulating water for abatement systems

Toxic and regulated exhaust gases generated during semiconductor manufacturing must be treated safely and effectively before discharge.

Abatement systems neutralize these gases using chemical reactions, which vary depending on the type of exhaust. To ensure proper operation, precise measurement and control of various fluids—including dilution gases, reactive gases, cooling water, and circulating water—are essential.

KOFLOC provides a comprehensive lineup of flow control solutions for abatement systems:

- – RK1200 and RK1400 series float-type flow meters for simple and reliable visual flow monitoring

- – MODEL 3660 series and FM01 series mass flow controllers for high-precision and responsive gas control

- – 2600-S series constant flow valves for stable and maintenance-free flow regulation of cooling and circulating water

These devices contribute to the safe and stable operation of gas treatment systems by ensuring accurate and consistent fluid control across various process conditions.

-

Wire Bonding

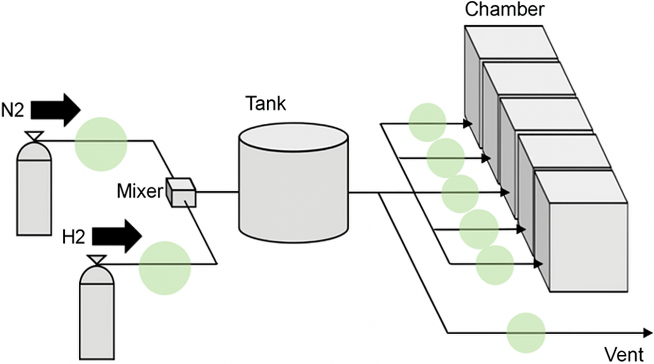

Measurement, generation, and control of forming gas (N2 + H2 mixture)

In the wire bonding process, semiconductor chips are connected to the lead frame—a metal structure on the substrate—using fine bonding wires.

To prevent oxidation of the lead frame and solder during bonding, the interior of the bonding equipment is purged with forming gas, a mixture of hydrogen and nitrogen.

KOFLOC offers comprehensive solutions for this application, including not only precise measurement and control of forming gas, but also gas generation and mixing systems.

- – RK1200 and RK1400 series float-type flow meters allow simple and accurate visual flow monitoring.

- – MODEL 3660 series digital mass flow controllers provide high-precision digital control for critical forming gas flow rates.

- – MODEL 2412 series precision needle valve with non-rotary needle ensures stable and accurate manual adjustment of forming gas, making it ideal for sensitive semiconductor processes.

If you have any questions, please feel free to contact us.