TECHNICAL SUPPORT

-

-

Technical information

Principle of Flow Control Valve

Actual example of flow control

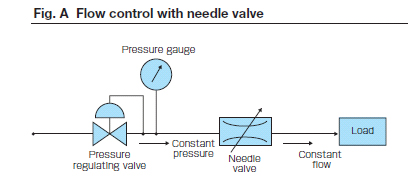

(1) Flow control with needle valve

The needle valve controls the opening of a small orifice in a channel with a bar-shaped needle, controlling the flow by changing the channel resistance. The valve thus acts as a resistance.

The flow changes when the pressure applied to the valve changes. Therefore, a pressure regulator is provided in the preceding stage as shown in Fig. A to make the pressure applied to the valve constant, thereby

obtaining constant flow. This is an inexpensive method which is commonly used when the pressure loss on the valve outlet side does not change. Use a simplified type, precision type, or bellows type needle valve according to the usage.

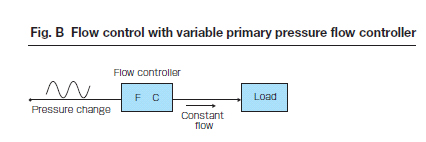

(2) Flow control with variable primary pressure type flow controller

The variable primary pressure (supply pressure) type flow controller is made by combining the needle valve (1) and a pressure regulator.

It can keep the flow constant even if the primary-side pressure changes.

(Fig. B).

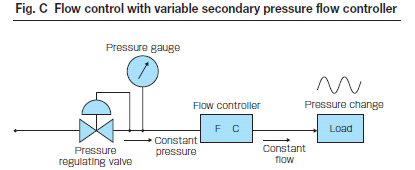

(3) Flow control with variable secondary pressure type flow controller

In methods (1) and (2), the flow will change if the pressure loss of a load in the subsequent stage is large.

In that case, a variable secondary pressure (outlet-side pressure: load pressure) type flow controller is used to control flow according to the flow sheet shown in Fig. C.

This flow sheet is complete with respect to pressure change, and is used basically for our gas mixing equipment. The primary-side pressure is controlled by a regulator, and the flow controller immune to pressure changes on the secondary side enables flow control free of the influence of the primary and secondary pressure.

Flow control characteristic CV value

1

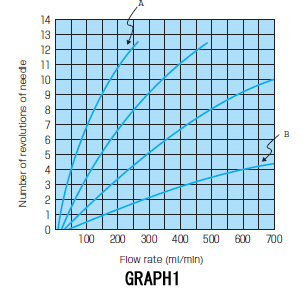

The fl w control characteristics of the KOFLOC flow control valves are all represented by the flow characteristics graph shown in GRAPH1.

In the characteristics table (B), the flow changes substantially when the valve is turned slightly, which makes setting difficult and usage unstable.

Therefore, it is necessary to select ser-vice conditions as close to the status (A) as possible.

2

KOFLOC manufactures valves individually to ensure they match the service conditions.

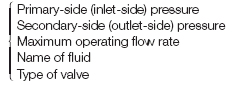

Simply select the type of valve and specify the supply pressure (primary pressure), outlet pressure (load pressure:

secondary pressure), and maximum operating flow rate, and then we will manufacture a flow control valve with the best control characteristics.

Even if there is no table or graph like the ones shown here, we can select the best valve.

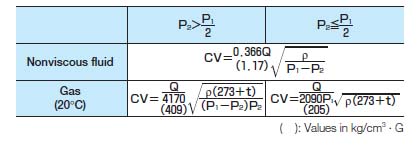

The CV value used as the flow characteristics of needle valves and the like is explained below.

The CV value is a kind of flow coefficient, indicating the approximate flow through a valve when a certain pressure is applied.

P1: Primary-side absolute pressure [MPa·abs]

P2: Secondary-side absolute pressure [MPa·abs]

Q: Flow rate [m3/h]

ρ: Specific gravity (Gas: Air = 1, Liquid: Water = 1)

3

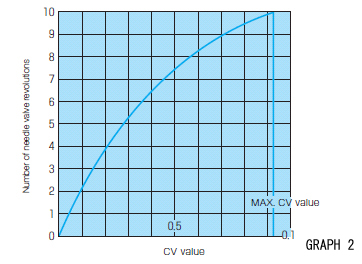

The CV value of a needle valve changes as shown in the GRAPH₂ when the valve opening changes. Setting aside the control characteristics, the problem is the flow rate, not selection of an actual valve.

Therefore, the importance point is the maximum CV value shown in the GRAPH₂.

4

This text shows the maximum CV values of all needle valves.

When the maximum CV value is substituted in the aforementioned equation to find Q, the maximum flow rate under the operating pressure and temperature conditions is derived.

However, application of this method becomes more difficult as the flow becomes more precise, so use it just as a rough standard.

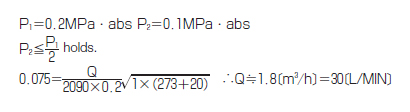

Suppose 0.075 is the CV value, for example. Let's find the flow rate when the primary pressure (gauge pressure) is 0.1 MPa and the secondary pressure in the atmosphere (gauge pressure) is 0 MPa in cases where air of 20°C is to be controlled. In terms of absolute pressure, the gauge pressure will be 0.1 MPa · abs.

5

Therefore, the flow of 30 l/min can be controlled when the valve

operates between the fully-open and fully-closed states under the

above conditions.

Flow characteristics of needle valve

1

The needle used for respective valves comes in various types ac-cording to the flow.

2

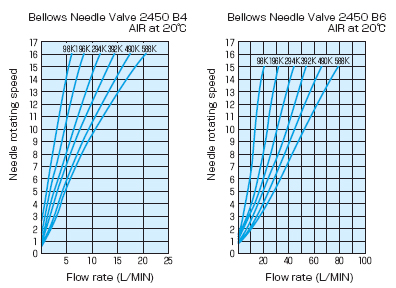

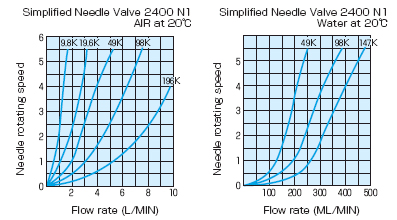

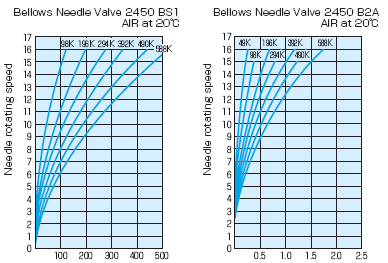

The graph shown below summarizes the flow characteristics of representative KOFLOC needle valves.

There may be a slight difference when respective needle valves are actually used because of operating condition errors and instrument errors, as well as the characteristic

summarization based on differential pressure.

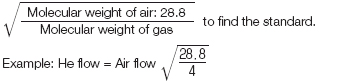

In the case of a gas, air is used as a representative for summarization; in the case of other gases, multiply the flow rate by

3

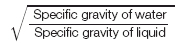

In the case of a liquid, water is used as a representative; in the case

of other liquids, multiply the flow rate by

4

When the viscosity is high, however, contact us for the specific coef-ficient of viscosity.

CAUTION -Precautions on use of needle valves-

Needle valves do not guarantee constant flow continuously.

Opening/closing of other valves, temperature changes, and impact will cause the flow rate to change.

Please determine the period to monitor and readjust the flow rate.

Selection of Kofloc valves

1

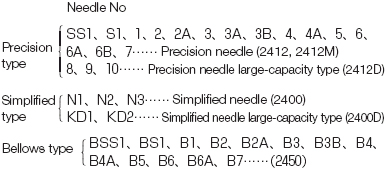

Needle valves are divided into two main types: the simplified type and the precision type.

The simplified type has a needle valve knob made integral, and the needle rotates to control flow.

Meanwhile, the precision type has a needle and knob made separately, and the needle moves directly without rotation. The precision type excels in both ease of flow setting and stability. Select an appropriate type in terms of price and accuracy according to the intended usage.

2

The Model 2203 (flow controller) is a constant flow valve that maintains a constant flow when the secondary pressure changes.

Model 2204 (flow controller) maintains a constant flow at the outlet side when the primary flow changes.

The Model 2412 precision needle valve is used for very small flow, while the Model 2412D is used for a wide range of uses as a largecapacity type.

The Models 2400 and 2400D are simplified versions of the Models 2412 and 2412D.

The bellows seal Model 2450 is a low leakage valve that is suitable for use in a vacuum line. The Model 2412M is a precision needle valve equipped with a dial gauge.

3

KOFLOC selects an optimum needle according to the operating

conditions.

4

Advise us of the above, and we can offer the best type irrespective of the needle number.

Of course, we can also manufacture a needle valve according to the specified needle number.

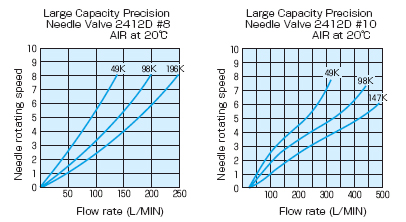

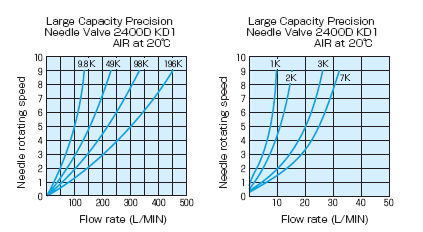

Exampleof Characteristics of KOFLOC Model 2412D/2400D Needles

Large Capacity Precision Needle Valve 2412D #8,#10

Large Capacity Precision Needle Valve 2400D KD1

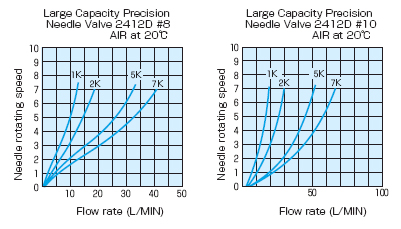

Large Capacity Precision Needle Valve 2412D #8,#10

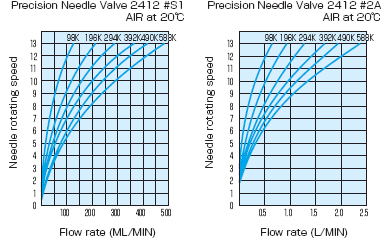

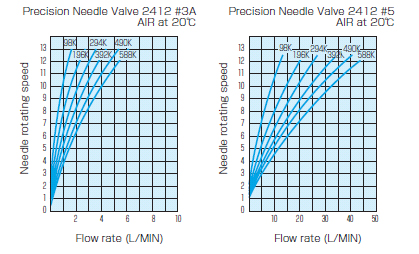

Example: Characteristics of Model 2412 Needle

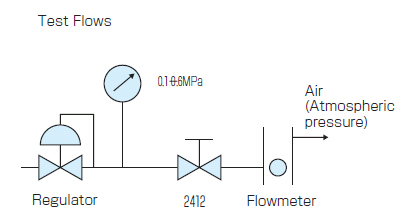

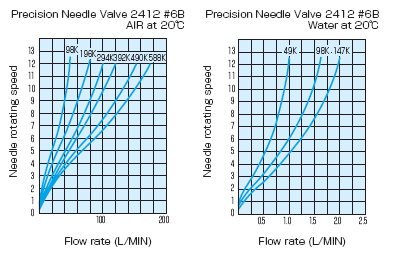

Test Flows

Precision Needle Valve 2412 #S1, #2A

Precision Needle Valve 2412 #3A, 5

Precision Needle Valve 2412 #6B AIR/Water

Example of Characteristics of KOFLOC Model 2400/2450 Needles

Test Flows

Simplified Needle Valve 2400 N1 AIR/Water

Bellows Needle Valve 2450 BS1, B2A

Bellows Needle Valve 2450 BS1, B2A